Most marathon runners will tell you that the last leg of the race is the hardest. In the same vein, the final leg of freight delivery is often the most complicated. This final leg – the delivery of a package from the warehouse or fulfillment center to the customer’s address – is known as the “last mile,” though the actual distance can vary.

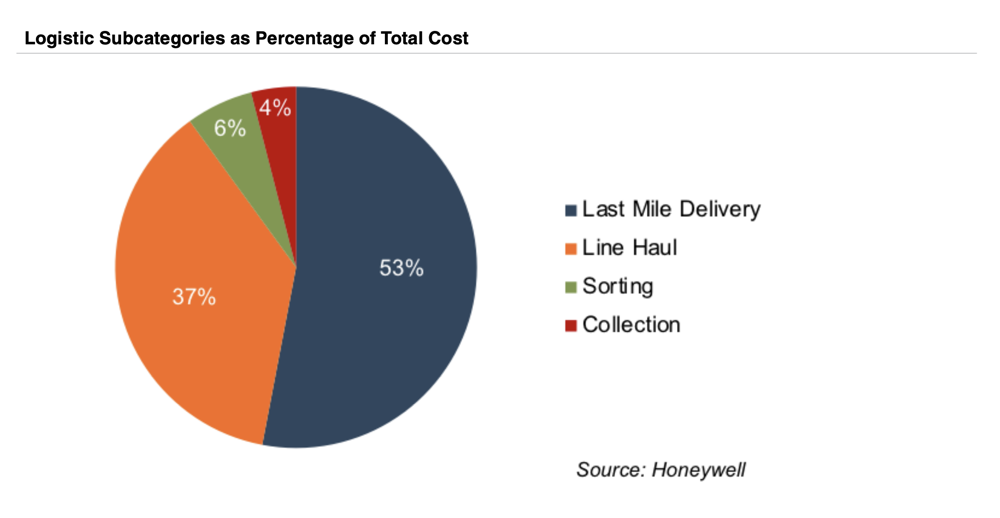

But why is the last mile important and how are companies attempting to “solve” the last mile problem? One reason is the increased popularity of online shopping. Another reason is its relative expense compared to other aspects of the logistics chain. According to a Honeywell estimate, last mile logistics account for 53% of total logistics cost. Finally, as more of the world’s population moves to urban areas in the coming decades, last mile difficulties will only grow. Rural last mile delivery poses its own challenges, such as low customer density. Although greater population density in cities is advantageous for concentration of deliveries, the traffic congestion and lack of parking cancel out many potential benefits. UN estimates put 55% of the world population living in an urban population right now, but projections show that this number will increase to 68% by 2050.

In response to this problem, many companies have turned to robotics and autonomous vehicles. On June 5th, 2019, the FAA approved Amazon for testing of its “Prime Air” drone delivery service, which promises 30 minute drone delivery of packages under five pounds. The FAA also sanctioned UPS to use drones in its commercial deliveries. UPS has been using drones to deliver supplies to the WakeMed hospital campus in Raleigh, NC multiple times a day since early in 2019.

On a more grounded note, other major delivery companies are considering non-drone solutions. FedEx unveiled its “SameDay Bot” in late February, and will test it this summer in certain markets (including Memphis). Likewise, Amazon announced in January of 2019 that it would be trialing its “Amazon Scout” delivery robot in a Seattle suburb. Both of these robots are essentially boxes with wheels attached, designed to roll on level sidewalks during daylight hours.

Ford, bucking this trend, is producing a human-like robot called “Digit” with two arms and two legs, and it hopes that a nonwheeled design will be better able to navigate the obstacles of an urban environment. “Gaining access to a customer’s door often requires walking through obstacles, including going up stairs and dealing with other challenges, which can be hard for robots with wheels to do,” notes Ken Washington, Ford’s chief technology officer. Ford, which developed this robot in partnership with Agility Robotics, hopes to use Digit in conjunction with its current autonomous vehicle delivery testing, where it partners with Postmates.

Solutions will become increasingly important as e-commerce sales increase both in volume and in percentage of total retail sales. With the use of unmanned ground vehicles and drones expected to increase by 20 million devices by 2020, this technology will become increasingly commonplace.

Originally published in Mercer Capital's Transportation & Logistics Newsletter: Second Quarter 2019